TabCN-5-7-9C Tablet Press

TabCN-5-7-9C machine is a single sided tablet press which is capable of producing tablets with diameters up to 12mm.

Tablet Press TabCN-5-7-9C

TabCN-5-7-9C machine is a single-sided tablet press that is capable of producing tablets with diameters up to 12mm. With minimal operator and maintenance training demands, the machine provides a cost-effective solution to small and medium-batch tablet production.

It is a continuous automatic tablet press that can be used in the pharmaceutical, chemical, food, and electronic industries.

- The machine is fully-enclosed, made of stainless steel, and meets the G.M.P requirement.

- It has transparent windows so that press conditions can be observed clearly and the windows can be opened.

- Reliable safety sealing system and dust-proof system. Cleaning and maintenance are easier.

- The surface of the rotary table is specially treated to maintain surface gloss and prevent cross-contamination.

- Adopt frequency conversion speed control device for electrical speed control, which is easy to operate, smooth to run, safe, and accurate.

- All transmissions are arranged inside the machine to keep the parts clean.

- Equipped with an overload protection device, it can automatically stop when the pressure is overloaded.

- The machine is equipped with an electromagnetic brake motor and other safety protection devices.

- The compression parts are entirely separated from the driving mechanisms.

- All spare parts to be in contact with the pharmaceuticals are made of stainless steel or the surface being treated specially for non-toxicity & corrosion proof.

- Machine speed, the depth of filling, and the thickness of the tablet could be adjusted.

- Easily remove parts for quick machine maintenance.

| Model | TabCN-5C | TabCN-7C | TabCN-9C |

| Dies | 5 set | 7 set | 9 set |

| Max. Pressure | 60 kN | ||

| Max. Dia. of Tablet | 20 mm | ||

| Max.Depth of Filling | 15 mm | ||

| Capacity | 9000 tablets/h | 12600 tablets/h | 16200 tablets/h |

| Power | 110V 60Hz / 220V 50Hz 2.2kW | 110V 60Hz / 220V 50Hz 2.2kW | 110V 60Hz / 220V 50Hz 2.2kW |

| Weight | 260kg | ||

| Dimensions | 480x630x1100 mm | ||

Product video:

Rotary tablet press advantages:

- Guarantees a higher output as high production levels can be achieved with a minimal amount of labor.

- The higher output of 110000 to 16200 tablets per hour saves time and enables you to meet the needs of large-scale production.

- It reduces the wastage of material.

- It allows independent control of both the weight and hardness of tablets.

Main application:

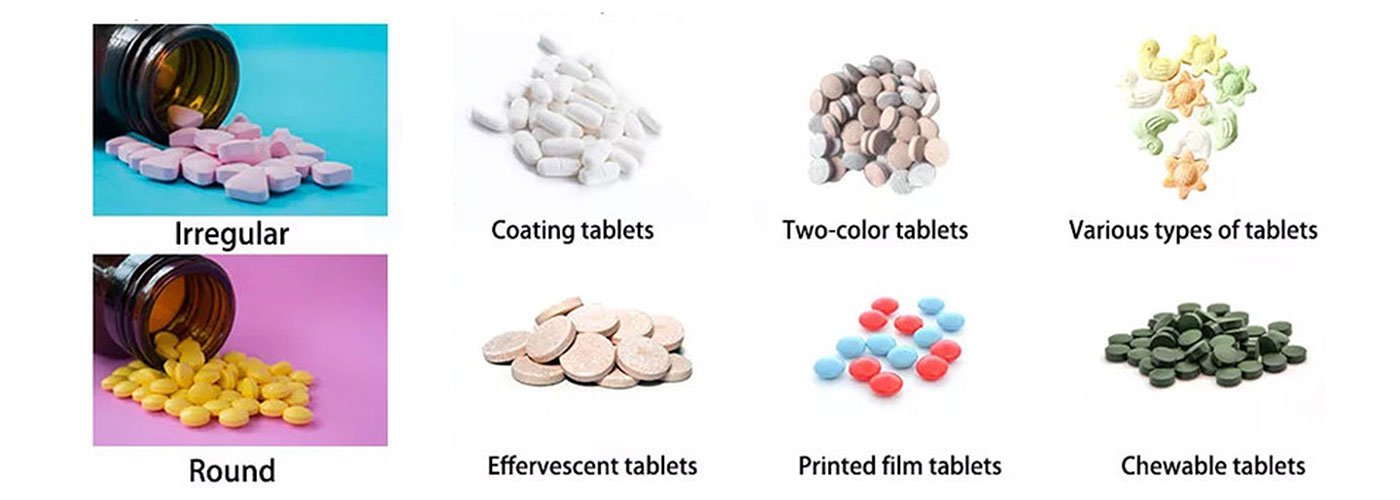

This machine is a single-press type, continuous automatic tablet press for pressing granular raw materials into tablets. It is mainly used in the pharmaceutical industry and also the chemical, food, electronic, plastic, and metallurgical industries.

Main application:

Peripheral Cover

The peripheral cover is fully-sealed and made of Auce stainless.easy to clean without dirty corner.

Structure Of Rotary Table

The rotary table is a main component which consists of upper/lower bearings and main shaft.

Structure Of Rail

The rail is cylinder cam and plane concaved wheel consisting of upper/lower rail,as well as The track of movement of upper/lower impact lever.

Filling-Adjustment Unit

The filling adjustment unit is designed for adjusting the weight of tablets.

Tablet-Thickness Adjustment Unit

This unit is designed for adjusting the thickness of tablet.

Feed Unit

Feed unit consists of feeder,bucket rack,column,adjustable screw and bucket.

Outlet