TabCN-35-37-43C Tablet Press

Totally-enclosed transparent windows are used at the working area, with little dust pollution and good sealing performance. All parts are made of stainless steel or have specially-treated surface to prevent cross contamination, conforming to the GMP requirements.

Tablet Press TabCN-35-37-43C

Totally-enclosed transparent windows are used at the working area, with little dust pollution and good sealing performance. All parts are made of stainless steel or have specially-treated surface to prevent cross contamination, conforming to the GMP requirements.

- Besides high maximum pressure, there is a pre-pressure device to prolong the pressing time and make the tablet quality better.

- High rotation speed of turntable and double-sided tablet pressing make production highly efficient.

- The control part adopts PLC and the operation panel adopts the color touchscreen display, making the operation simple.

- Totally-enclosed transparent windows are used in the working area, with little dust pollution and good sealing performance. All parts are made of stainless steel or have specially treated surfaces to prevent cross-contamination, conforming to the GMP requirements.

| Model | TabCN-35C | TabCN-37C | TabCN-43C |

| Punch quantity | 35 set | 37 set | 43 set |

| Punch form | IPT | ||

| Max. tablet pressure | 80 kN | ||

| pre-pressure | 60kN | ||

| Max. filling depth | 18 mm | ||

| Max. tablet diameter | 25 mm | 32 mm | 18 mm |

| Production capacity | 189000 tablets/h | 199800 tablets/h | 232200 tablets/h |

| Max. turntable speed | 45r/min | ||

| Motor power | 7.5 kW | ||

| Machine weight | 3500 kg | ||

| Dimensions | 1170*1290*1900 mm | ||

Product video:

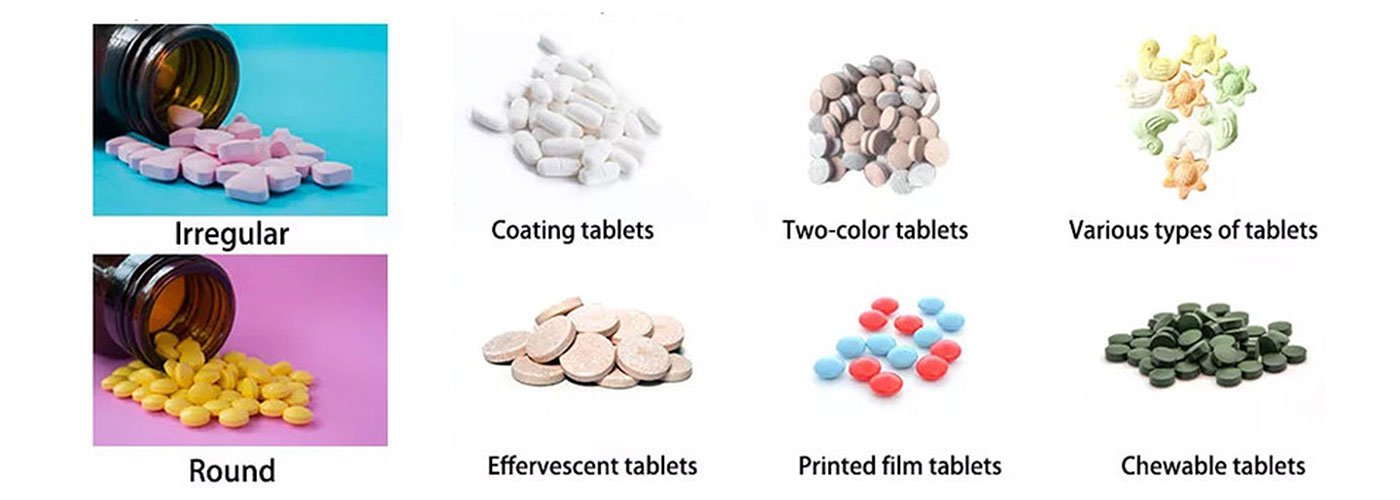

Rotary tablet press advantages:

- Guarantees a higher output as high production levels can be achieved with a minimal amount of labor.

- Higher outputs of 16200 tablets per hour save time and enable you to meet your large production demands.

- It reduces the wastage of material.

- It allows independent control of both the weight and hardness of tablets.

Main application:

This machine is a single-press type, continuous automatic tablet press for pressing granular raw materials into tablets. It is mainly used in the pharmaceutical industry and also the chemical, food, electronic, plastic, and metallurgical industries.

Main application:

Peripheral Cover

The peripheral cover is fully-sealed and made of Auce stainless.easy to clean without dirty corner.

Structure Of Rotary Table

The rotary table is a main component which consists of upper/lower bearings and main shaft.

Structure Of Rail

The rail is cylinder cam and plane concaved wheel consisting of upper/lower rail,as well as The track of movement of upper/lower impact lever.

Filling-Adjustment Unit

The filling adjustment unit is designed for adjusting the weight of tablets.

Tablet-Thickness Adjustment Unit

This unit is designed for adjusting the thickness of tablet.

Feed Unit

Feed unit consists of feeder,bucket rack,column,adjustable screw and bucket.

Outlet