TabCN-15-17-19C Tablet Press

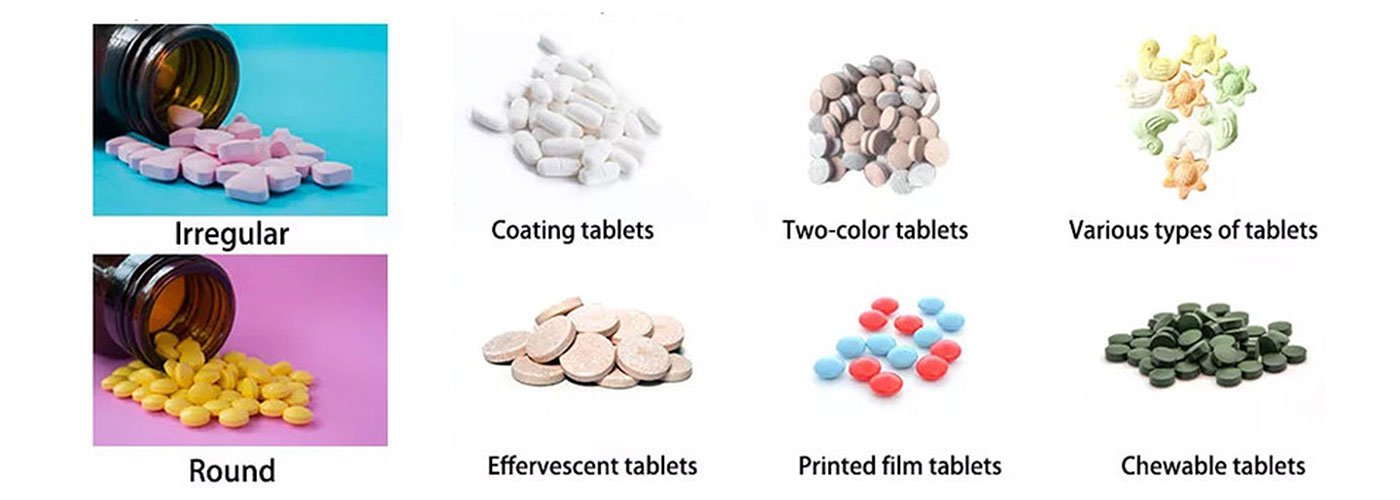

This single-pressure type machine with automatic rotation and continuous tablet pressing can be applied to press granular raw materials into various ordinary and special-shaped tablets.

Tablet Press TabCN-15-17-19C

This single-pressure type machine with automatic rotation and continuous tablet pressing can be applied to press granular raw materials into various ordinary and special-shaped tablets. It is mainly used in electronics, food, daily necessities and pharmaceutical industries. The totally-enclosed outer housing is made of stainless steel, conforming to the GMP standard. Besides, as it is equipped with transparent observation windows, the working status of the machine can be cleared observed. In addition, they can be opened to make internal cleaning and maintenance easy.

- With such features as high pressure, wide tablet range, and the ability to make tablets of various shapes including ordinary, special-shaped, and ring-shaped tablets, it is especially suitable for the production of small batches and varieties of products.

- With mechanical and electrical integration, all controllers and regulating devices are centralized at one side of the machine, making the operation much easier.

- The upper and lower pressing wheels adopt rolling friction, which helps reduce the working resistance and the power loss.

- Pressure overload protection device: The safety unloading device of the pressing wheels is balanced by the spring, and its working pressure is adjusted by the spring sleeve. It will unload automatically when overpressure occurs. At the same time, the indicator light will send an overload signal and stop the machine automatically. This contributes to making pressure stable, reducing impact and vibration, and protecting the punch from overpressure.

- The adjustment and control mechanisms of filling amount, tablet thickness, and rotation speed are all under centralized control, which makes operation easy.

- This machine adopts an enclosed oil-immersed worm gear drive to reduce power loss and prolong the service life of worm gear.

- The peripheral cover is a fully-enclosed structure and the sealed pressing chamber and driving mechanism are completely separated, which can prevent dust from flying and avoid cross-contamination of oil.

- This machine is equipped with an independent vacuum cleaner, whose high efficiency in dust collection ensures the normal operation of the machine.

| Model | TabCN-15C | TabCN-17C | TabCN-19C |

| Punch quantity | 5 set | 7 set | 9 set |

| Max. tablet pressure | 60 kN | ||

| Max. table diameter | 22 mm | 20 mm | 13 mm |

| Max. filling depth | 15 mm | ||

| Max. tablet thickness | 6 mm | ||

| Speed of turntable | 37 r/min | ||

| Production capacity | 35,000 pc/h | 40,000 pc/h | 42,000 pc/h |

| Motor power | 3/960 kW, 380V/50Hz | 2.2/960, kW 380V/50 Hz | |

| Overall dimension | 615*890*1415 mm | ||

| Weight | 700kg | ||

Product video:

Main application:

This machine is a single-press type, continuous automatic tablet press for pressing granular raw materials into tablets. It is mainly used in the pharmaceutical industry and also the chemical, food, electronic, plastic, and metallurgical industries.

Detail images:

Peripheral Cover

The peripheral cover is fully-sealed and made of Auce stainless.easy to clean without dirty corner.

Structure Of Rotary Table

The rotary table is a main component which consists of upper/lower bearings and main shaft.

Structure Of Rail

The rail is cylinder cam and plane concaved wheel consisting of upper/lower rail,as well as The track of movement of upper/lower impact lever.

Filling-Adjustment Unit

The filling adjustment unit is designed for adjusting the weight of tablets.

Tablet-Thickness Adjustment Unit

This unit is designed for adjusting the thickness of tablet.

Feed Unit

Feed unit consists of feeder,bucket rack,column,adjustable screw and bucket.

Outlet